How Are Smartphones Manufactured?

Ever wondered what life your phone had before you? We can help! There are over 1.43 billion smartphones sold annually worldwide, making the production of these devices an important one to ensure that the end product is the best on the market. Whether you have an iPhone 14 or a Samsung Galaxy 22, all smartphones go through the basic principles of manufacture.

As buyers and sellers of some of the latest phones, the process of how they came to be is interesting to us. Whether you’re wondering if “it’s time to sell my smartphone” or looking to buy a new device when you recycle your phone, it has a significant impact within the creation of new devices. Join us as we explore the life of your phone before it ended up in your hands, and the importance recycling has on the industry.

Let’s start where it all begins, prototypes

Whether it’s a new phone in the series or a new mobile altogether, a team of researchers, developers, and board directors will create the first design of what they want the phone to offer. This could mean looking into what works well on other phones or what customers are looking for to make their lives easier. All the experts will work together to create the first model. This will feature how the team wish for the phone to look, function and feel, with all the necessary components it should offer. It gives a chance to improve existing technologies or deliver entirely new ones. The most critical factor is – what will make this device stand out from all the others?

Software installation

Once the final design has been agreed upon, development moves on to installing new software. This is when the software team brings the phone to life with all the pre-decided technology and how the operating system works. This stage includes the camera functions, the menus and everything that makes the phone work.

There is often a bit of toing and froing at this stage, allowing the developers and software team to fix any issues that may have come up in the installation. These issues can range from storage issues, battery failings or even miscalculations of designs. Once these are ironed out, and the phone is ready, it can move on to the next stage.

Testing…1….2…3…testing…

So, before this sparkling new handset can be mass-produced and sent to be sold worldwide, it must go through thorough testing. This testing stage is possibly the most important as it prevents overheating phones from causing danger to life, malfunctioning software and issues that will prevent this phone from being the best. Through this stage, the phone is certainly put through its paces to highlight anything that can go wrong when in use.

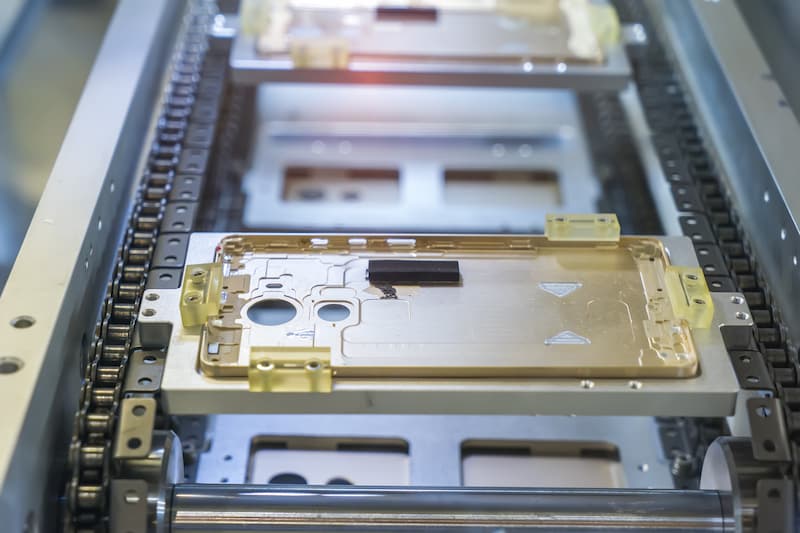

Mass production

Once the phone has been through the scrutiny of the testing stage and any kinks worked out, it is now ready for mass production. Interestingly, throughout this process, smartphones are usually provided with code names. Codenames prevent leaks of the phone’s specification and design, ending up with competitors or users before they enter the market. The biggest mass producer of electronics is Foxconn. They make items for Apple, Amazon, Nintendo, Nokia, and PlayStation…well, the list is endless. This stage is also important to make sure each phone is correct. Although most of the manufacturing is done on a conveyer belt with the assistance of machines, each phone goes through testing to ensure there are no anomalies in the production line. They are also given protective stickers to prevent any damage to the device in transit.

Pack your bags…you’re off!

Once the phone is put together, it heads off to packing, where the new device is placed in its shiny new box along with any manuals, accessories (if it has any) and, of course, the charger. Phone packaging has significantly reduced over the years. This happened to help minimise the impact on the environment, and with many homes changing to USB plug sockets, the humble plug is becoming less and less necessary.

Shipment and distribution

Before the phone’s release, all the devices are shipped off to an undisclosed storage facility, where they are stored and ready for the official launch. Then, once the marketing team has worked out a strategy, the phone can be shipped worldwide to various other storage units and eventually distributed once the phone’s launch has begun.

Which parts of the phone are made from recycled items?

Well, pretty much any part of the phone can be made from recycled parts. Mobile phones are made from various materials, including metal and plastic, which can be extracted and recycled to produce new products. The extracted parts that still have life in them can be used to produce refurbished phones. Mobile phone trade-in services help to offer our customers almost brand-new handsets for a fraction of the price of buying one directly from the manufacturer.

Every element is broken down, taken from the device and collected for the unusable parts from broken phones beyond repair. Once there is a significant amount of the same material, this can often be melted down to produce enough new material to use in new products. For example, if a circuit board from your phone is snapped, it cannot be placed into another device. The individual circuit board is not enough to melt down alone, but if you have loads of them, you may have enough to produce a completely new object.

The importance of recycling a phone

As we have explained, almost every element of the phone can be reused. Although it may not be in a condition to make into a new phone or be brought back to life as a refurbished one, its elements may come back as something new entirely. So, trading in your old phone is essential for producing new items.

There are many reasons to recycle your mobile phone, but helping the environment is probably the most important. Whilst in use, the phone is safe as houses, but when discarded and left to rot in a landfill, it can leak toxins and gases. These all contribute to greenhouse gases and can negatively impact the environment. By using sell my mobile services like ours, you can prevent this from taking place, knowing we will ensure that it’s taken care of correctly. Not only that, but you help provide new resources for new devices without the need to find raw materials.

Get cash when you recycle your phone

Although there should be no need for an incentive to help the environment, we at Mazuma like to throw in a bonus when you decide to sell your mobile with us. We offer competitive rates for most new handsets with the speediest service, so why not check it out today? So, whether you wish to sell your iPhone or sell your Samsung phone, earn a bit of money for your pocket and do your bit for the environment too!